Boiled wool fabric: The Production Process

Boiled wool fabric is the perfect winter companion. Its warmth and durability is what most people look for. Wool itself is an impressive, natural material that has great properties from the ground up. Through the boiling process, these properties are further strengthened. The result is a thick, soft, and durable fabric, which is ideal for use in our high-quality products.

HOW IS GIESSWEIN BOILED WOOL ACTUALLY PRODUCED?

At Giesswein, it takes four easy steps to produce our high-quality boiled wool fabric. This boiled wool fabric gets generated into our high performance merino wool. It is this fabric which we feature throughout our footwear products. We make sure the yarns of wool or wool-mixes are the highest quality, to ensure our customers receive a product that will last them for numerous seasons. Breaking down the individual steps, you can enjoy the journey we take to creating our boiled wool fabric.

STEP 1: CHOOSING THE BOILED WOOL FABRIC YARN

In general, boiled wool is made of wool or wool-mixes. The quality of the final boiled wool product thus depends upon the selection of its base materials. Ensuring we have the correct base is important to us as we want to provide our customers with footwear and clothing that can be used throughout the year. In our production process, only the finest, high-quality yarn makes the cut.

STEP 2: KNITTING THE WOOL FABRIC

After the yarn is selected, it’s then knitted. In order to make sure that we don’t get any cramped hands or stiff fingers, our knitting machines do this step for us. Depending on each product’s specific needs, we use different machines and patterns for each one.

For our unique “3D Stretch Merino Wool”, we’ve even developed a special knitting technique. This technique increases the flexibility of the merino wool's properties, which makes for an especially comfortable fabric. This technology can be seen in a wide variety of our men's sneakers and women's sneakers. By increasing the flexibility of the material in our footwear, it makes for a comfortable fit, without sacraficing on stability. You could gorget painful pressure points, as the fabric hugs your feet in all the right places. Perfect for those long walks in the fresh countryside.

STEP 3: BOILING THE WOOL FABRIC

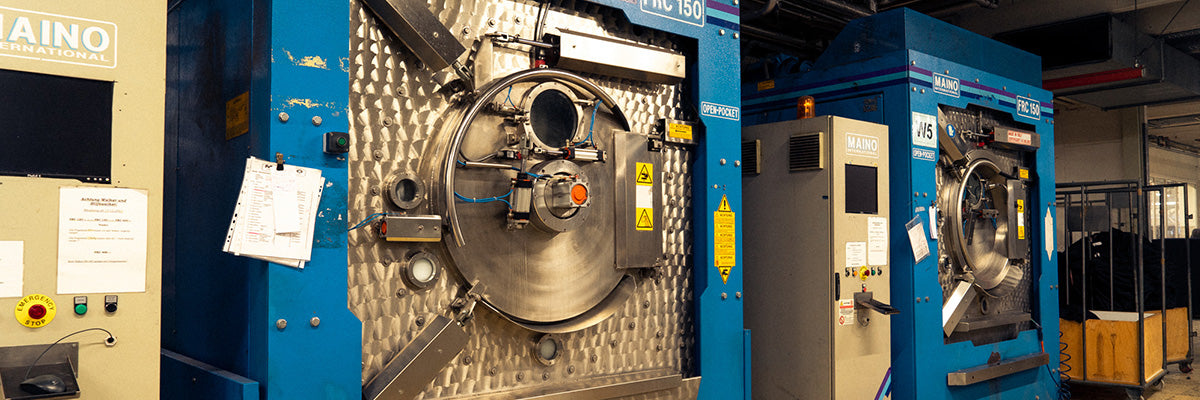

Step three is one of the most delicate parts of the process. Just like cooking the perfect steak require finesse, you require finesse. Our boiling process incorporates this requierment as it needs the correct temperature and timing.

It is in this step when the knitted products are washed in large machines with the supervision of our experienced employees. Through this process, the boiled wool's surface is roughened. Once completed the results present themselves by the forming of countless air chambers. Having the ability to create tiny air chambers allows your skin to breathe when in contact with the boiled wool fabric. This ability is perfect for our selection of footwear, especially for our breathable trainers for summer. Not only does this step in the process result in breathability, it also leaves the boiled wool fabric more durable. This durability is better at sealing in the warmth, which is an advantage when wearing our products throughout the winter.

During the boiling process, we only use fresh water without any artificial additives. It is this combination that allows us to reuse up to 90% of the water that we use during production processes. The achievement is just one of the ways we are committed to our green strategy.

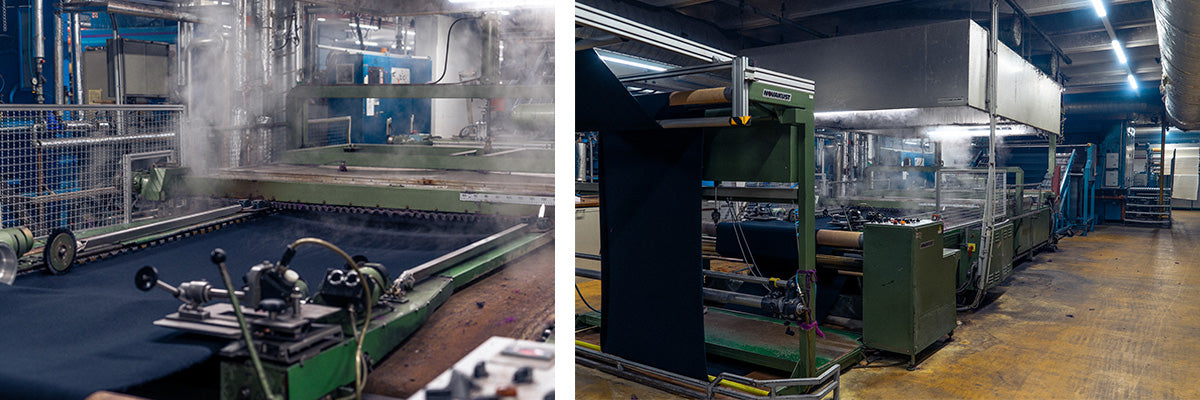

STEP 4: REFINING THE BOILED WOOL FABRIC

The final step in our production process for boiled wool fabric is drying the wool out and working it further. The techinical term for this is 'refining' the wool. There are many different ways in which we carry out our refining process. One way in which we do this is by steaming the wool. When we steam the boiled wool fabric we're able to refine it into the desired thickness.

Once we have achieved our desired thickness for our boiled wool fabric, we then move to our hemming machine. We often refer to this piece of equipment as our “make-the-wool-soft machine” as it leaves the high-quality fabric feeling softer than ever. Having super soft wool in our range of footwear is important to us as when your feet are comfortable, you can enjoy your walks for longer. Whether you are popping to the shops or embarking on a hill climb, we have a range of everyday trainers your feet can enjoy.

After completing those four simple steps, we are left with our high-performance boiled wool, the 3D Stretch Merino Wool. You can find this boiled wool fabric in a range of our comfortable trainers and even our hiking shoes, the Wool Cross X Alpine.

THE BENEFITS OF BOILED WOOL FABRIC

Boiled wool fabric has numerous benefits to promote as the natural properties of wool are further strengthened throughout the boiling process. During the boiling process, the wool becomes even more:

- Long-lasting and durable

- Breathable

- Wind resistant

- Dirt- and water-repellant

- Insulating

- Wrinkle-free

GIESSWEIN 3D STRETCH MERINO WOOL

Throughout our three generation ownership, we have found a way to produce our boiled wool fabrics with even higher quality. These products are softer than ever before due to our hard work and dedication to achieving the highest quality fabric. Over our many years of experiences, trial and error, we have created the special knitting and boiling techniques. These techniques are what we've developed to be able to craft our “3D Stretch Merino Wool”. This technology is incorporated into numerous products including our breathable summer sneakers. After crafting the process we found our process makes traditional merino wool even more flexible and comfortable. It is thanks to processes like this that we’re able to craft our wonderful products with such high quality and comfort right here in our facilities in Tyrol, Austria.

Our unique merino wool has fantastic properties which are all incorporated into our footwear and clothing. The five main benefits can be seen as:

- Temperature regulating

- Super lightweight

- Odor-free fabric

- Moisture wicking

- Flexibility

The combination of these qualities work in perfect harmony to achieve a comfortable feel against your skin. What's more, when you wear a pair of our barefoot shoes with merino wool, you can go sockless! Enjoy the barefoot feeling on any adventure you embark upon.

ABOUT GIESSWEIN

Giesswein is a family run wool company, which spans back over three generations. During that time we have been reinventing the positive attributes wool has to offer. We specialise in merino wool and virgin wool, which create the structure to our cosy slippers.